The Manufacturing USA Institute Model

Manufacturing USA institutes are designed to enable large-scale collaboration and develop manufacturing technologies that address national priorities. Each institute has a specific technical focus area with a well-defined mission; institutes cannot substantially duplicate the work of other institutes in the Manufacturing USA network. As public-private partnerships, institutes receive start-up funding from the federal government through an open competition and must provide funds at least equal to the government investment with resources from their innovation ecosystems.

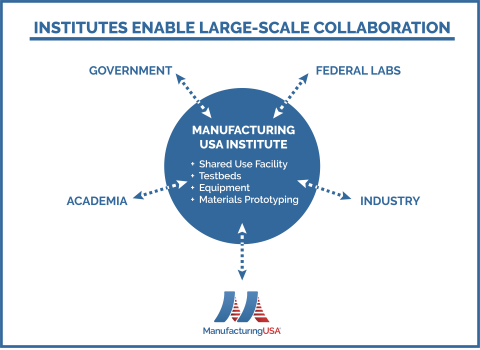

Each institute convenes partners to create a neutral and effective collaboration space for pre-competitive applied R&D, solving significant challenges—those that are unlikely to be solved by a single entity alone. This environment enables large-scale collaboration and pre-competitive applied research among government, federal laboratories, academia, and industry, which helps startups, small and medium manufacturers, and industry leaders address scale-up challenges to support technology transition. The institute's infrastructure provides a unique setting with shared access to cutting-edge equipment, capabilities, and knowledge. The institutes lead efforts to address the skills gaps for the evolving workforce in their respective technology areas. They ensure that workers are trained with the skills needed for the new technologies while broadening the current workforce to address worker shortages. Their efforts help ensure what's invented here is made here by a skilled American workforce.

Any organization, such as a university or college, a non-profit, a trade association, or a for-profit company1, can lead institutes and their ecosystems. The sponsoring entity must be able to represent the ecosystem fairly and be the financial and organizational lead of the institute. However, the consortia must be industry-driven with clear missions and unique technology focus areas based on critical industry needs and national priorities. The institutes are tasked with accelerating the accessibility of advanced manufacturing capabilities so emerging technologies are available to all manufacturers. They must also facilitate the transition of institute-developed technology to drive economic growth in their manufacturing sectors.

How do these ecosystems come together and operate?

In alignment with its mission and national priorities, a federal agency launches a funding opportunity to award a consortium lead for a new Manufacturing USA institute to address a critical need or gap. This opportunity may be based on feedback from industry about their manufacturing needs or an identified national priority. Organizations submit proposals to establish an institute in the Manufacturing USA network, and the selected proposer convenes many partners across the innovation ecosystem for that technology focus area. Engaging a diverse partnership, including large and small companies, state economic development agencies, non-profits, universities, community colleges, and other workforce development partners, is needed to access the cross-cutting expertise and resources necessary to deliver impact.

The formation of an institute relies heavily on collaborative leadership that can bring together representatives from multiple sectors. The selected proposer designs the institute to enable large-scale collaboration within the parameters of the Manufacturing USA model, which include:

- A public-private partnership with an industry-driven technology focus

- Structure and governance based on the needs and risk-culture of the chosen industrial sector

- Collaboration with other Manufacturing USA institutes

- Participation in cross-network activities and meetings, including the Manufacturing USA Council

- Commitment to sustaining the ecosystem

Leadership undertakings involve many activities, such as acquiring and managing institute facilities and equipment and securing funding sources. Leadership must continually grow their ecosystems and engage their members in technical and workforce activities. Leadership must also communicate the institute's achievements and coordinate with the Manufacturing USA network to ensure nationally recognized impacts.

Institute goals and investment evolve based on member engagement and input, allowing for industry-driven direction for the institute. As such, institutes should recruit a diverse group of members to ensure the direction of the institute is defined by all critical stakeholders in their technology area, resulting in an inclusive innovation ecosystem working to improve our way of life, strengthen our economy, ensure our national security, and empower the next generation.

members join institutes for transformative gains

Institutes create value for industry participation that drives the co-investment required to match the federal investment. In Fiscal Year 2022, the institutes in the Manufacturing USA network had a nearly 3 to 1 investment match—they attracted $307 million from state, federal, and private funds in addition to $109 million in base federal funding.

Members find value in access to R&D funding and technical expertise, shared use and pilot production facilities to test new technologies, and collaboration opportunities with other institute members. These collaboration opportunities can lead to members connecting with new customers and suppliers. Case studies have shown that when an advancement from an institute is implemented at a member company, it produces clear output and efficiency results. Other benefits of becoming a member may include:

- De-risking and acceleration of technology development through project funding and collaboration

- Input and influence on industry roadmaps and direction

- Access to education and workforce development programs designed to upskill and diversify the talent pool and funding for workforce initiatives

- Access to member content, tools, and intellectual property through technical licenses, software libraries, smart manufacturing profiles, educational content, and webinars

- Networking events and increased visibility, from small business and prime suppliers to academia and federal laboratories and agencies

- Awareness of future national manufacturing needs

- Co-location with supply chain

- Small business incubators

Become Part of the Movement to Strengthen Domestic Manufacturing

The United States is making an unprecedented $1.7 trillion investment in the industrial base to restructure or expand critical domestic manufacturing sectors, strengthen our global competitiveness, and meet climate goals. The Manufacturing USA Network has a proven record of connecting people, ideas, and technology to solve industry-relevant advanced manufacturing challenges.

Learn more about how to become part of the Manufacturing USA network, and opportunities to partner in our newest institute competitions.

1 For-profit organizations must be organized and operated in the United States with majority domestic ownership or control.