Network’s First Institute Is Poised to Help Transform Manufacturing

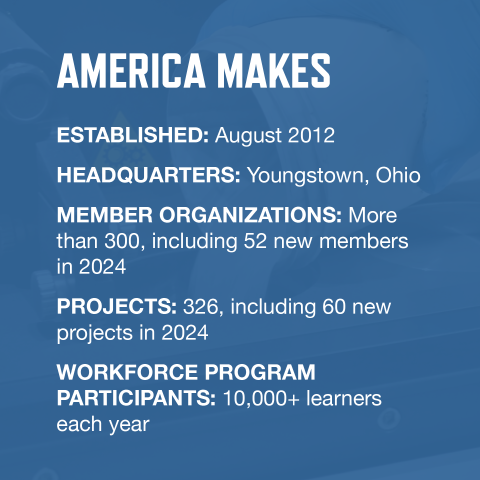

America Makes, the National Additive Manufacturing Innovation Institute, was the first manufacturing innovation institute in what would become the Manufacturing USA network. Since 2012, America Makes has been a driving force in the advancement of additive manufacturing (AM), convening public-private collaboration among government, academia, and industry to accelerate technology adoption and support U.S. manufacturing competitiveness and national security. Its work focuses on three areas:

- Advancing technology

- Growing the AM workforce

- Expanding the AM ecosystem

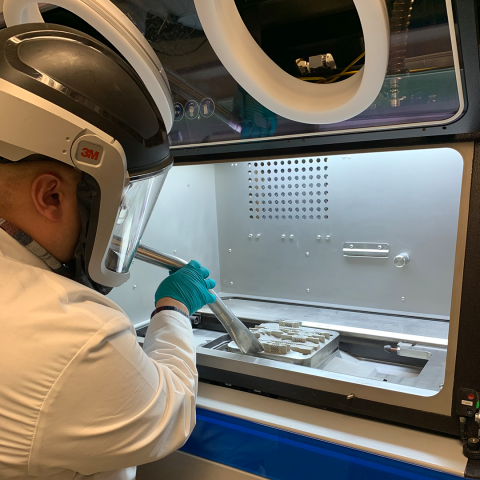

Additive manufacturing (or 3D printing) has the potential to transform manufacturing by building objects layer by layer, based on digital design files, allowing for the creation of complex geometries that would be difficult or impossible with traditional methods. AM requires fewer parts, allows for greater design freedom to make complex and highly customized parts, reduces material waste, and enables rapid design iterations and on-demand production. America Makes helps advance AM technology through its process of vetting industry needs and priorities, securing funds, and coordinating collaborative projects undertaken by members.

America Makes has worked to grow and enhance the skills of the AM workforce by promoting skills training for credentials and identifying career pathways. The institute stimulates interest in 3D printing and AM among middle and high school students by developing educational resources, partnering with schools and organizations, and hosting events and competitions.

The institute is also committed to promoting knowledge-sharing within the broader AM ecosystem, and is working to expand the reach and impact of AM to a wider range of applications, in both private industry and government.

America Makes’ Industry Achievements

Here are some key accomplishments from America Makes’ efforts to advance the additive manufacturing industry and its future workforce.

Ecosystem Development

- Crisis response infrastructure: During the COVID-19 pandemic, America Makes created and led the Advanced Manufacturing Crisis Production Response (AMCPR) program to alleviate part shortages in many industries, as well as to create an infrastructure that rapidly responds to national, regional, and local supply chain shortages. The institute worked with numerous federal agencies and the Department of Defense (DoD) to strengthen the U.S. response capability to future crises through the AMCPR Exchange portal, a Strategic Roadmap and Playbook, and an Impacts Report.

- The Regionalization Strategy Playbook: The institute created a roadmap to guide regional expansion efforts in new geographic areas, covering topics such as how to tap into existing local ecosystems, roles and responsibilities, milestones, value propositions, costs, and potential revenue streams. The playbook helps America Makes and the Manufacturing USA network more rapidly scale their impact across different regions of the country.

Workforce Development

- AMNation: This is a portal that the institute created for members and partners that offers centralized access to a wide range of educational outreach materials, from curriculum guides to online training modules. The America Makes Education and Workforce Development team also created the AMJobs site, which profiles people in the AM industry. It also initiated the ongoing efforts of the Additive Manufacturing Portal for Education.

- Manufacturing Engineering Education Program (MEEP): MEEP was created to address the need to upskill the workforce to produce systems and components that safeguard technological superiority for the DoD. MEEP audited over 40 industry-recognized credentials, identified gaps in training curricula, created 33 eLearning courses, and scaled the program to nearly 9,000 unique students.

America Makes Project Success Stories

Integrating Additive Manufacturing into Casting and Forging Operations

Metal castings and forgings (CF) are among the most critical components for our national defense and commercial supply chains, but there has been a 67 percent reduction in the number of U.S. foundries since 2000. America Makes and its stakeholders embarked on a project to identify how the integration of 3D printing could help CF industries achieve improvements in efficiency, design flexibility, and product quality. The group identified challenges impacting their supply chains, how additive manufacturing could mitigate those issues, and the investments needed to integrate additive manufacturing into CF operations. The use of AM provides compelling advantages at low production volumes, which is crucial for the Defense Industrial Base to be able to respond quickly and in an economically viable manner.

Innovative Solutions to Support Low-Cost Air Force Sustainment

Legacy U.S. Air Force aircraft often require parts that are difficult to procure as they become obsolete. Parts may no longer be manufactured or stocked, product documentation can be poor or non-existent, and the costs of manufacturing can be prohibitively high. Additive manufacturing offers the potential to increase part availability, thereby enabling mission readiness. America Makes and its partners developed a three-phase program, Maturation of Advanced Manufacturing for Low-cost Sustainment , to provide rapid, low-cost sustainment solutions. The program has provided rapid response solutions to ongoing projects and initiated new projects to support the Air Force’s challenges at several bases. Its impact is ongoing and will be felt for many years.

Q&A with John Wilczynski, Executive Director of America Makes

John Wilczynski has been Executive Director of America Makes since 2019. He joined its sponsoring organization, the National Center for Defense Manufacturing and Machining, in 2009, and he transitioned to the America Makes team when it was founded in 2012. He was the institute’s Director of Technology for five years prior to becoming the lead executive.

Here he discusses a few of America Makes’ highlights as the Manufacturing USA network celebrates its 10th anniversary — and shares his outlook for the institute’s next 10 years.

Looking back, what stands out as a success when building your ecosystem?

Since the inception of the institute, we have placed an emphasis on roadmapping. We recognized the opportunity to be the voice of industry — documenting and coordinating its needs and driving meaningful actions. By developing clear plans, outlining actionable steps, and guiding the initiation of projects, we have made a significant impact. Today, hundreds of technology-centered projects are thriving due to the programs we helped shape and coordinate.

The role of the institute is to convene, coordinate, and catalyze — and we have been driving success in these areas from the start.

What have been some of the challenges in building an ecosystem?

One significant challenge facing the AM ecosystem has been in the area of standards. While we don’t develop standards ourselves, we do play a crucial role in coordinating them. Different industry sectors — such as automotive, aerospace, welding, petroleum, and electronics — have each developed unique standards tailored to their needs. In 2016, recognizing the need for coordination across sectors, America Makes and ANSI established the Additive Manufacturing Standardization Collaborative (AMSC). The AMSC’s objective is to accelerate the development of additive manufacturing standards and specifications across sectors, while also accommodating the needs of stakeholders in each industry.

Challenges arise when certain issues are addressed by one sector but not another, or when research and development is needed to establish a new standard. This is where we come in. We work with the ecosystem to identify standards gaps, which the standards development organizations can then address. The coordinating role is a real opportunity for us. By aligning efforts and clarifying responsibilities, we can enable the industry to move forward more effectively.

What are the challenges to adoption?

Additive manufacturing is a powerful tool and a gateway to innovation across industries. It’s a technology that stands out — if this were a schoolyard dodgeball game, we would be one of the first picks. From enabling mass customization to replacing or enhancing systems in the aerospace industry, AM has proven its potential. Now, the challenge is bringing these innovations to market.

While awareness of AM exists, there is still a significant gap in education. People need to understand the full scope of what’s possible with AM. That’s where the next big opportunity lies.

What are the keys to adoption?

Still, there are relatively few people skilled in applying AM design principles to their projects. Since many systems are not frequently updated, “designing for additive” represents a significant area for growth.

Take metal 3D printing, for example. In the current quest for space exploration, many components in the new propulsion systems are made with AM. This technology enables great consolidation of internal part geography, simplifying complex designs. For context, the visual comparison of the SpaceX Raptor engine — versions 1, 2, and 3 — showcase how AM can drastically reduce the number of parts and streamline engine complexity.

What do the next 10 years look like for America Makes?

Here are five ways we talk about the future of additive manufacturing:

- Scaling up: This is critical for us to compete and win on a global level as we face increasing pressure from foreign competitors.

- Materials data: The availability of materials data is crucial. People are willing to share findings and data, so we must seize the opportunity to leverage the information effectively.

- Regionalization: We must provide information to support communities in their journey to adopt additive manufacturing.

- Training programs: We must continue to grow the talent pipeline for AM. We do this through raising awareness and providing focused programs for students of all ages. We have realized growth in these areas over the past few years, but we need to do more to close the existing skills gap.

- Qualification and certification: These focus areas are essential to commercialize products and increase the adoption of production-capable technology.

What goals or innovations excite you most about America Makes’ next decade?

AM is a rapidly maturing technology — a gateway to other innovations. Our collaboration efforts span across Manufacturing USA institutes, unlocking transformative potential in diverse sectors. For example, large-scale AM wouldn’t be possible without robotics, and AM plays a pivotal role in advancing microelectronics and beyond. AM is more than a tool — it’s the driving force behind many of today’s manufacturing transformations.

10 Years of Innovation, Collaboration & Education

America Makes is part of the Manufacturing USA network, which was created to increase U.S. manufacturing competitiveness by connecting people, ideas, and technology. Learn more about 10 areas where America Makes and the rest of the Manufacturing USA network have made a significant impact since the network’s inception in 2014.

Learn More