Advancing Manufacturing Technologies and Domestic Supply Chains

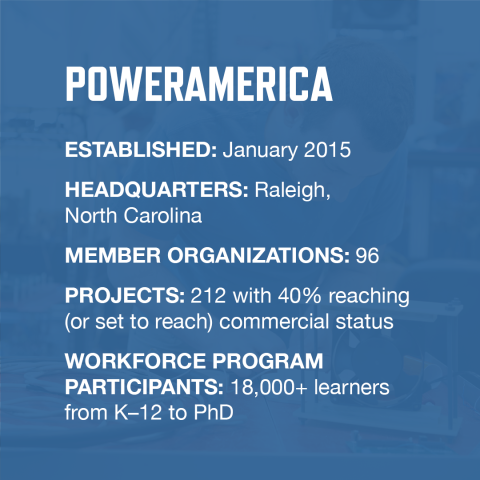

PowerAmerica celebrates its upcoming 10th anniversary as a Manufacturing USA institute having catalyzed super-efficient wide bandgap (WBG) semiconductor chips and power electronic systems. By fostering innovation, collaboration, and commercialization, PowerAmerica is strengthening the domestic supply chain and enhancing the resilience of this critical technology sector.

The institute works with public and private partners to develop leading WBG technologies, including power silicon carbide (SiC) and gallium nitride (GaN) semiconductors. These materials provide more powerful performance and dramatic energy savings than traditional silicon-based designs in an array of applications, such as electric vehicles, grid and renewables, industrial motor systems, consumer electronics, and data centers.

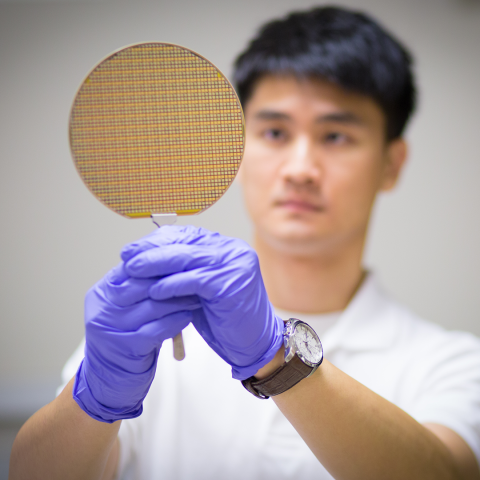

SiC is suited for high-power and high-voltage uses, such as electric vehicle chargers and power inverters for home solar systems. A key feature of SiC is its ability to tolerate high temperatures, making it ideal for demanding environments.

GaN devices, in contrast, excel in speed and compactness. Capable of switching on and off faster than silicon-based devices, GaN enables efficient power transfer within smaller, lighter designs, making it particularly suited for portable and compact charging applications.

WBG technologies have also demonstrated they meet the needs of next-generation high-voltage applications. These include grid modernization, power systems for manufacturing plants, photovoltaic farms, and multi-megawatt motor drives, paving the way for a more energy-efficient future.

PowerAmerica’s Industry Achievements

Here are some key accomplishments from PowerAmerica’s efforts to advance the WBG semiconductor industry and its workforce.

Ecosystems

PowerAmerica Technology Roadmap to Advance Wide Bandgap Semiconductor Adoption: WBG technologies have the potential to transform industries by significantly saving energy and reducing emissions while creating high-tech manufacturing jobs. The roadmap offers a comprehensive strategy to make WBG semiconductors cost-competitive with traditional silicon-based power electronics and accelerate the adoption of SiC- and GaN-based components in emerging markets and applications. Key highlights of the roadmap include:

- Identifying key markets and application areas for SiC and GaN power electronics

- Estimating time frames when they will be commercially viable

- Establishing performance targets that GaN and SiC technologies are expected to meet over time

- Acknowledging technical barriers to achieving those targets

- Agreeing on research activities needed to overcome those barriers.

This roadmap serves as a blueprint for advancing WBG semiconductor technology, ensuring its integration into next-generation power electronics and fostering an energy-efficient future.

Workforce Development

Comprehensive Training for Industry and Academia: PowerAmerica’s 2.5-day WBG short course provides in-depth training on all aspects of WBG semiconductor chip and power electronic technologies. Course instructors from more than a dozen universities and companies provide a balanced mix of academic insights and practical industry knowledge. To ensure relevance, course content is regularly updated to reflect the latest advancements in WBG technology. Each year, the course attracts more than 130 working professionals, university faculty, and graduate students, making it essential for those seeking to deepen their expertise and stay ahead in this rapidly evolving field.

PowerAmerica Project Success Stories

Establishing U.S. Production of Super-Efficient Semiconductors

PowerAmerica worked with X-FAB and other stakeholders from 2015–2020 to build the first open SiC chip factory in the U.S. Located in Lubbock, Texas, the X-FAB foundry operates under a collaborative model, providing fabrication capabilities to SiC semiconductor companies without in-house fabrication facilities. As the only high-volume SiC foundry in the U.S., X-FAB has become a vital resource for domestic SiC production, helping to curb the migration of critical SiC semiconductor manufacturing overseas. Notably, X-FAB’s impact extends globally, with many European and Asian companies now fabricating chips at the facility. Together with PowerAmerica, X-FAB is leveraging existing silicon economies of scale to lower the cost of manufacturing SiC devices, further solidifying the U.S. position in this technology. As evidence of its success with PowerAmerica, X-FAB was recently awarded up to $50 million under the CHIPS and Science Act to expand its SiC production capacity, ensuring continued growth and innovation in the sector.

A Holistic Approach to Strengthening the Power Electronics Supply Chain

By strategically growing its membership to include all segments of the WBG semiconductor supply chain, from design and fabrication to packaging and product integration, PowerAmerica is driving the development of a robust domestic supply chain for WBG semiconductors. Member organizations collaborate to identify and address pre-competitive challenges, leveraging the institute’s ecosystem for innovation and manufacturing. The membership includes six national labs, 21 leading universities with expertise in WBG power electronics, and industry giants such as Lockheed Martin, GE Aerospace, and Wolfspeed.

Q&A with Victor Veliadis, Executive Director of PowerAmerica

Victor Veliadis has been Executive Director and Chief Technology Officer at PowerAmerica since joining the Manufacturing USA institute in 2016. He discusses a few of PowerAmerica’s highlights as it reaches its 10th anniversary — and shares his outlook for the institute’s next 10 years.

Looking back, what stands out as a challenge when building your ecosystem?

The first thing I had in mind when we began was there had to be a strong value proposition for members — what do we offer them? We kept the membership fee at a low enough level that private sector managers could write a check without having to get approval from VPs and leadership, and universities could also easily participate. Our goal was to identify pre-competitive research projects that would be attractive to industry and help everyone. U.S. manufacturing had reached a point of outsourcing so much work overseas that national security was at risk. Our goal then, and still today, is building U.S. supply chain resilience and economic growth.

What are a few of your foundational successes?

We are helping the U.S. take the lead globally in SiC production. Back in 2016, way before the CHIPS and Science Act, we partnered with X-FAB to create the world’s first open SiC foundry. We stopped the bleeding of WBG chip fabrication going overseas, and we also created a place where foreign companies could come here to make chips. The X-FAB foundry provided multiple small companies that lacked their own SiC fabrication facilities with access to shared production and R&D capabilities. It allowed companies to showcase their technology. Some companies demonstrated their chips produced at high yields and were eventually acquired.

We want to do something similar with GaN semiconductor production, which has led to smaller and faster chargers for phones and laptops. GaN is largely fabricated overseas now, and we’d like to lead the charge in bringing much of that capacity back to the U.S.

We also have helped accelerate the adoption of WBG into power electronic systems at big companies like John Deere. And we’re seeing adoption by major cloud service providers at data centers, which is a huge opportunity.

What are the keys to increasing adoption of WBG technology?

Showcasing reliability will always be No. 1. Power electronics is a very conservative industry with an unwillingness to shift away from something that works. One of the challenges in adoption is that “efficiency” is not always a sufficient selling point. There is risk involved in adopting a new technology. Reliability and ruggedness have been big barriers. Will this new technology work for the lifetime of the system? We have to continue to demonstrate WBG capabilities and benefits. Showing how something can be a reliable improvement with a clear ROI is key to adoption. We also need a more robust supply chain to ensure longevity.

How do you approach workforce development for such a complex technology?

A key to our workforce development efforts is to educate university students at a high level for quicker deployment into the workforce. The knowledge trickles down if you are able to educate people who can train others.

One of the concerns with the commercialization of new technology is that manufacturers will not have the workforce. They need trained people to apply new tech. That is one of the reasons we collaborate with universities — to leverage their students. We have worked with about 30 universities so far. Their students are active participants in applied research projects and often get internships and jobs with companies that are involved in those projects.

Universities also help make industry connections to PowerAmerica.

What excites you most about PowerAmerica’s next decade?

We are excited to see SiC and GaN going full scale into commercial production. This technology has about a 20 percent market share of today’s power electronics. It can be 50 percent in the next five years. Competition is intense as the entire world is electrifying. For example, I mentioned data centers earlier. Data centers are struggling with increased demands from AI and electrification. Contemporary technology works, but it generates significant excess heat that is difficult to manage. And the lack of efficiency is costing us in terms of energy consumption and emissions. We can bring in GaN and SiC to increase efficiency.

What impact do you hope PowerAmerica’s work will have on U.S. manufacturing over the long term?

We have technology others don’t have, so we must continue our efforts to manufacture it here, provide great jobs, and build supply chain resilience. But when you are leading, you need to stay one step ahead so other countries cannot approach your products from a commodity perspective. We are helping drive down the cost of production, and we need to continue to streamline operations, reduce costs, automate processes, and do whatever it takes to remain competitive. The long-term impacts are economic growth, such as high-tech jobs, and national security benefits.

10 Years of Innovation, Collaboration & Education

PowerAmerica is part of the Manufacturing USA network, which was created to increase U.S. manufacturing competitiveness by connecting people, ideas, and technology. Learn more about 10 areas where PowerAmerica and the rest of the Manufacturing USA network have made a significant impact since the network’s inception in 2014.