Smart manufacturing architect, project leader, speaker

Olivia Morales’s job is to make sure manufacturing machines talk to each other, play nicely, and share data with both operators and the rest of the business where they work. It’s not as easy as it sounds, because most heavy machinery is built to be autonomous and run on special software known as operational technology (OT), while data sharing depends on connected operating systems and information technology (IT). Her job is all about how OT and IT interact.

Olivia is a Solutions Architect for CESMII, the Smart Manufacturing Institute, which is working to reduce production costs and complexity so all types of manufacturers can engage in advanced manufacturing. She collaborates with CESMII’s institute members, leading teams on both technical and complex problems to help them make products faster and better. Prior to joining CESMII, Olivia was a software engineer at Rockwell Automation.

Olivia’s area of focus involves working with data from the machinery and modeling how to improve manufacturing processes. This involves understanding how the machines operate and sharing information with each other to improve manufacturing processes. Her day may include writing code for a tech demo, reading technical specifications, talking to manufacturers about how they are using tools and equipment, tinkering and problem-solving to get data flowing, and developing training materials.

She has become a smart manufacturing thought leader. Olivia was a panelist at SXSW 2024 on Manufacturing USA’s panel: “Reimagining Energy Use with Digital Technologies.” Additionally, she participated in an invitation-only roundtable on innovations for a more sustainable future, presented by Axios. Because of her leadership in this area, Olivia was able to lead an important session on information modeling at IME (Informa Markets Engineering) West. For working to secure the future of smart U.S. manufacturing, Olivia Morales is a Modern Maker.

Q&A with Olivia

How did you find your way to working in advanced manufacturing?

I didn't really know what engineering was when I chose to go to an engineering school, but I knew I liked problem-solving, science, and math. Initially, I majored in Mechanical Engineering, but I took a class that made me fall in love with the logic of Computer Engineering (which is distinct from software engineering), my eventual major.

Similarly, I didn't know much about manufacturing or automation when I joined Rockwell Automation's rotational program. I was interested in rotations because I didn't really know what I wanted to do. (I am still figuring that out.)

During the rotational program, I learned about the automation technology involved in manufacturing. It was cool. It had a lot of the same type of logic and problem-solving that made me love computer engineering to begin with. There's something really satisfying about making a light turn on or a conveyor move.

My first job after rotations was as a Full Stack Software Engineer. The problems I was solving became more complex, but I still got to work with hardware and software, including web development. Ultimately, I landed at CESMII as a Solutions Engineer. Instead of product development and solving very specific problems, little by little, I'm now responsible for helping to solve broader problems in manufacturing. I've learned even more about manufacturing through this role and am constantly amazed by the variety of areas for innovation and creativity.

What is the most challenging part of your job?

Balancing my time on near- and long-term tasks. Sometimes this means saying no to things or pushing back on requests from peers and leaders.

What is the best part of your job?

Seeing real change in the industry

- When the lightbulb moment happens with someone I'm working with and they understand something AND how to build it.

- Seeing our technology vision come to life with real technology.

- Being able to help a manufacturer use data they had no way of leveraging and seeing their confidence grow – both in themselves and in the underlying principles.

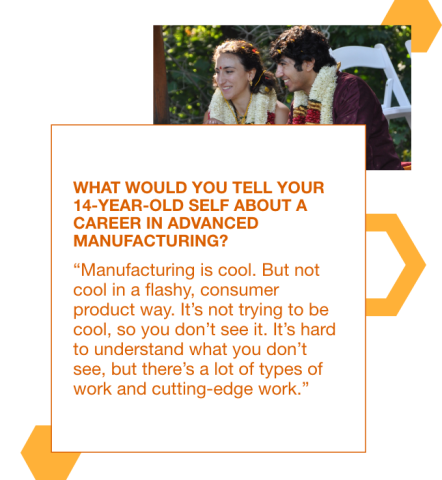

What would people be surprised to learn about manufacturing or your role in it?

In manufacturing, there's a lot of innovation, data, technology, etc. Manufacturing isn't mainstream, but it's fundamental to our everyday lives. There are innovation constraints that are different from other industries and so much opportunity for big changes. That's exciting.

What advice do you have for someone new to the industry?

- Shadow people you don't work with directly.

- Ask questions, especially the dumb ones.

- Take a lateral role that gives you a breadth of perspective, and maybe it'll help you discover a path you wouldn't have otherwise taken.

- Seek out a mentor. People want to help, but remember that advice is only as good as the experience of the person giving it.

What makes you excited to go to work on Mondays?

I love my job, but I love my free time. I'd be lying if I said I was looking forward to Mondays. However, I've blocked off Monday afternoons for focus work because deep focus is necessary for any job.

What activity gives you the most energy?

Something outdoors – a walk, a hike, biking, camping, sitting by the beach.

What hobbies make you better at your career?

- Running – it can simultaneously clear my mind, re-energize me, and help me process thoughts.

- Financial Planning – it requires a macro and micro perspective, and research.

- Travel – connecting to other people and places finetunes the empathy I bring to my job, and it helps me check myself.

How does the work you do impact the world?

Our mission is rooted in energy reduction by creating more efficient manufacturing processes and reducing wasted effort. We are fundamentally changing the way that manufacturers use technology. We are bringing together competing companies to collaborate for the common good.