The manufacturing employment gap has existed for years, but some manufacturers have built great work cultures and evolved with societal changes to successfully build talent pipelines. In some areas, local stakeholders have created education and workforce development (EWD) programs that utilize local manufacturers and specialty partners to feed those pipelines.

So why has it been so hard for other manufacturers and communities to do the same? It’s a paradox: how do you replicate what makes an impact in a local community, especially a disadvantaged one, so that it has a national impact?

The need to reduce the worker shortage has never been more urgent, according to the National Association of Manufacturers (NAM), which notes 2.1 million manufacturing jobs could be unfilled in 2030. NAM points out the lack of skilled labor was the industry’s major challenge even before the loss of about 1.4 million manufacturing jobs during the early days of the pandemic. Though about two-thirds of those jobs have been recouped, the manufacturing workforce dynamic is largely unchanged over the past 25 years:

- PERCEPTION AND PIPELINE: There are not enough people pursuing careers in manufacturing; in fact people under the age of 25 make up only 8% of the manufacturing workforce.

- PREPARATION: Many future workers do not have the skills needed for current or future careers in manufacturing.

- RECRUITMENT: The pathway to good jobs and careers is not always clear. There is a need to connect skilled workers to good jobs.

- RETAINMENT: There is a need to provide skills to develop careers and retain existing workers.

Despite the obvious need for nationwide training, developing large-scale workforce programs has proven difficult for a variety of reasons – lack of alignment on awareness, funding, curriculum, standards for certifications, access to equipment and instructors, and more. What works in a community in the Southeast may not work in the Midwest - or there may not be resources to replicate successful programming.

But several of the institutes in the Manufacturing USA® network have arrived at formulas for workforce programs that can be replicated and scaled. Manufacturing USA is a national network created to secure U.S. global leadership in advanced manufacturing through large-scale public-private collaboration on technology, supply chain, and education and workforce development.

There are scores of successful education and workforce programs among the 17 institutes in the network that span the spectrum from K-12 to mid-career opportunities.

The Key to Scaling Programs is a Model That Can Be Replicated

Building a regional talent pipeline amounts to an economic development driver, as companies seek out areas in which they will have access to desired skills. But even the best-run programs need industry to have a seat at the workforce development table in order to be sustainable. Local manufacturers are increasingly being asked to share the costs of building a talent pipeline by donating staff time to education and workforce development programs and equipment for training.

To scale a program nationally, the key starting point is the program model. The program must be easily replicated or adopted for different emerging technologies. It must be a win-win-win for:

- PARTICIPANTS: The desired outcomes will vary with participants, from exposure and enthusiasm with students to entry level jobs and career advancement. There must be tangible results.

- MANUFACTURERS: They must see an increase in their talent pipeline that leads to hires.

- ADMINISTERING ORGANIZATION: The entity that administers the curriculum and markets the program, must also benefit, such as from increases in enrollment to additional funding or new partnerships.

Scaling a workforce program is not unlike a franchise model in the business world. The workforce program originator must pivot from managing and running the program itself to enabling and guiding others to do so. The overall structure must facilitate growth, and sustainability within a region or ecosystem.

Here is a look at success stories from the network: entry level (America’s Cutting Edge, by IACMI), mid-career (Operation Next from LIFT), and K-12 students (FlexFactor®, from NextFlex).

America’s Cutting Edge Offers Easy Entry, Hands-On High-Tech Training

IACMI, The Composites Institute, and the University of Tennessee launched the America’s Cutting Edge (ACE) training program CNC machining in 2020. ACE has had more than 5,000 participants, from all 50 states, the majority of whom are new to machining. There are now locations in nine states. It’s a hybrid approach that begins with free online learning to attract participants. The bookends for the ACE program are the workforce development model and cutting edge technology.

The ACE model is a hub-spoke design that depends on being in a location with a strong industrial base. The hub is a sponsoring entity that markets the program locally and provides leadership and mentorship. A hub could have as few as two spokes or grow to include 10 to 20, according to Joannie Harmon, IACMI’s Vice President, Workforce Development. The spokes are high schools, community colleges and trade schools that supply instructors and facilities for hands-on learning. ACE trains the trainers on the new technology.

The curriculum begins with about 6 hours of free, self-guided online work, primarily video content with quizzes. The next step is a free 32-hour in-person bootcamp that features a rapid deployment of actual training. Students are working on a machine within the first two hours of in-person training; you might not get that same opportunity in your first term at a technical or community college.

On the technology front, ACE introduces the MSC MillMax service for hands-on training. It was developed by MSC, Oak Ridge National Laboratory, and the University of Tennessee. MSC MillMax uses a digital readout from the machine, takes into account the historical information about that machine, and informs the software to adjust its settings to eliminate chatter and vibration. The operator sees a dashboard display that is either green or red, so they can make machine adjustments in real time for speed, feed rates, or width and depth of cuts. Operators no longer need to know the nuances of the machine.

One of ACE’s newest locations, at St. Cloud State University in Minnesota, is taking a different approach to training with a 53-foot semi-trailer as a mobile training center, ideal for reaching rural communities.

Operation Next Provides Mid-Career Access to Speciality Certifications

LIFT launched its Operation Next program in 2017 at the Fort Campbell Army base in Kentucky to provide training in advanced manufacturing skills for active-duty personnel who are within six months of separation from service. The program has about 600 graduates, is now in 11 states and territories, and has been expanded to include reservists, veterans, military spouses, dependents 16 years old and older, and, in some cases, civilians.

The curriculum includes a mix of self-paced learning, classes, and in-depth, in person, guided instruction for one of four key job areas (welding, CNC machining, industrial technology maintenance, and robotics technician). Graduates devote about 400 hours to complete the program and receive a specialty certification that is recognized through the industry.

The Operation Next model is based on two key pillars: LIFT provides the curriculum and funding for tuition and an education partner, such as a technical college or community college, provides marketing and recruitment, equipment and instructors. The program also is dependent upon buy-in from the military base leadership to allow active duty service members the time to commit to the program before the participants separate from the military.

The key to success is a dedicated person on location to raise awareness and market the program. “It takes a lot of work to get people interested and enrolled in these types of programs,” said Joe Steele, LIFT Vice President, Communication and Legislative Affairs.

It also takes a lot of funding to pay for tuition. Following the successful pilot, in 2019, LIFT received a grant from the Department of Defense’s Manufacturing Engineering Education Program (MEEP) to expand Operation Next to the locations it is in today. That grant expires this fall; LIFT continues to seek additional funding from federal, state or other sources to ensure a sustainable future.

FlexFactor Gives Students Exposure to Business and Innovative Technology

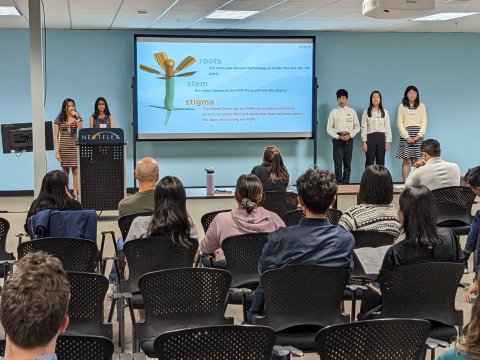

NextFlex’s FlexFactor is an awareness building program for high school and middle school students. It puts students in the shoes of business leaders facing real world opportunities and challenges that flexible hybrid electronics help to solve. FlexFactor has had 15,048 students go through its program as of summer 2023. The program is in 13 states and 31 areas, which NextFlex describes as ecosystems.

FlexFactor is a six-week program that includes a tour of a manufacturing facility and a team-based project in which students must work together to identify a problem and design a product solution that uses flexible hybrid electronics. They also must develop a business plan and present a pitch to hypothetical investors.

The program works well, according to Courtney Power, NextFlex’s Deputy Director of Education and Workforce Development, because connections to the emerging technology, industry, and higher education are woven throughout the program. The tangible benefits include:

- Students, often from under-served communities, can visualize themselves joining an industry that they otherwise might have never imagined joining. They gain a deeper understanding of advanced manufacturing as well as the tools and skills needed for different careers.

- It promotes “durable learning,” which refers to deep and lasting knowledge retention, because there often is not just one way to solve an issue.

Ultimately FlexFactor is a win for all of the stakeholders as students grow from the project experience, the industry partner is building a pipeline for future talent, and the program engagement entity also can drive its enrollment, exposure, and engagement.

Other Institutes are Adapting FlexFactor’s Project-Based Learning Model

FlexFactor’s success led the DoD to invest $5 million from MEEP to replicate the model. America Makes, the ARM Institute, BioFabUSA, IACMI, MxD, NIIMBL, and RAPID have adopted the model to meet their respective emerging technology. Spark Photonics, a private sector company that is a member of AIM Photonics, has also adopted the model.

NextFlex created FlexFactor against the backdrop of flexible hybrid electronics, but the underlying model, which NextFlex has made available to these other organizations under the MEEP grant, is curriculum agnostic, modular in structure, and does not require equipment. The program is easily adaptable to other technology foci, while maintaining the core learning progression (identify a problem, design a product, build a business model, and pitch investors) that has been the key to its success.

Each ecosystem requires a program engagement entity (such as a community college or a science center), a program manager to deliver the programming to students, and a local industry partner to host tours and help dispel myths about manufacturing jobs. While there is often a lot of interest from communities in adding a similar program, it can be a challenge to gain the institutional support and necessary staffing commitments for a program manager.

The spinoff programs are experiencing success. Almost 1,500 students in the 2022-23 school year completed IACMI’s SkillCrafters program that follows this model for composite materials, and BioFabUSA’s BioTrek program reached more than 500 high school students in New England in the 2022-23 school year.

Empowering the Current and Future Advanced Manufacturing Workforce

The institutes’ workforce development programs are helping to prepare the current and next generation for rewarding, living-wage jobs that will strengthen U.S. manufacturing and contribute to stronger local, regional, and national communities.

In 2022, the institutes collectively worked with over 2,500 member organizations to collaborate on more than 670 major technology and workforce research and development projects and engaged over 106,000 people in advanced manufacturing training. State, industry, and federal funds contributed $416 million to these activities.

To learn about the many ways in which institutes are helping prepare the workforce for future high-tech jobs, visit our manufacturing workforce development page.